$120.00

This course is designed for training oilers, mechanics, and millwrights as well as for the multicraft needs of process and manufacturing facilities. Participants are trained to recognize various types of lubrication systems and their maintenance requirements, including ring, bath, splash, constant level, and forced feed lubrication systems, as well as understand how they operate. Participants also learn the importance of following lubrication schedules, how to change common types of oil filters, and how to properly handle and store lubricants to prevent lubricant contamination.

This is the first lesson in the Industrial Lubrication Library. This lesson explains the concept of lubrication and friction, and demonstrates the benefits of a proper lubrication program.

The second lesson explains viscosity as well as the properties of common solid, semi-solid, and liquid lubricants are described as well as the benefits associated with synthetic lubricants and the functions of additives and inhibitors. Common types and causes of lubricant contamination are described and proper methods of lubricant storage are demonstrated.

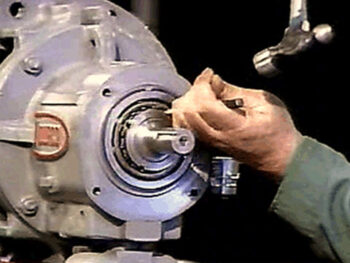

The third lesson T trains participants to recognize various types of lubrication systems and their maintenance requirements, including ring, bath, splash, constant level, and forced feed lubrication systems, as well as understand how they operate.

This is the final lesson in the Industrial Lubrication Library. Participants also learn the importance of following lubrication schedules, how to change common types of oil filters. This lesson explains the purpose of filters and the importance of filter maintenance in lubrication systems. Additionally, the lesson indicates the benefits of oil sampling and analysis and identifies several factors, which can cause lubrication failure.

2503 Robinhood Suite 200

Houston, TX 77005

Phone: +1 (713) 461-5200

Email: Sales@PetroEd.com

© Indaptive Technologies, Inc. | Privacy Policy | Licensing models & policies